Eco-Friendly Solutions for Recycling Transformer Oil with Modern Techniques

Eco-Friendly Solutions for Recycling Transformer Oil with Modern Techniques

Blog Article

Secure the Atmosphere With Trustworthy Transformer Oil Recycling Provider

The value of transformer oil recycling can not be overstated, specifically in the context of ecological preservation. The inquiry stays: just how can organizations properly select a recycling copyright that aligns with their ecological goals?

Relevance of Transformer Oil Recycling

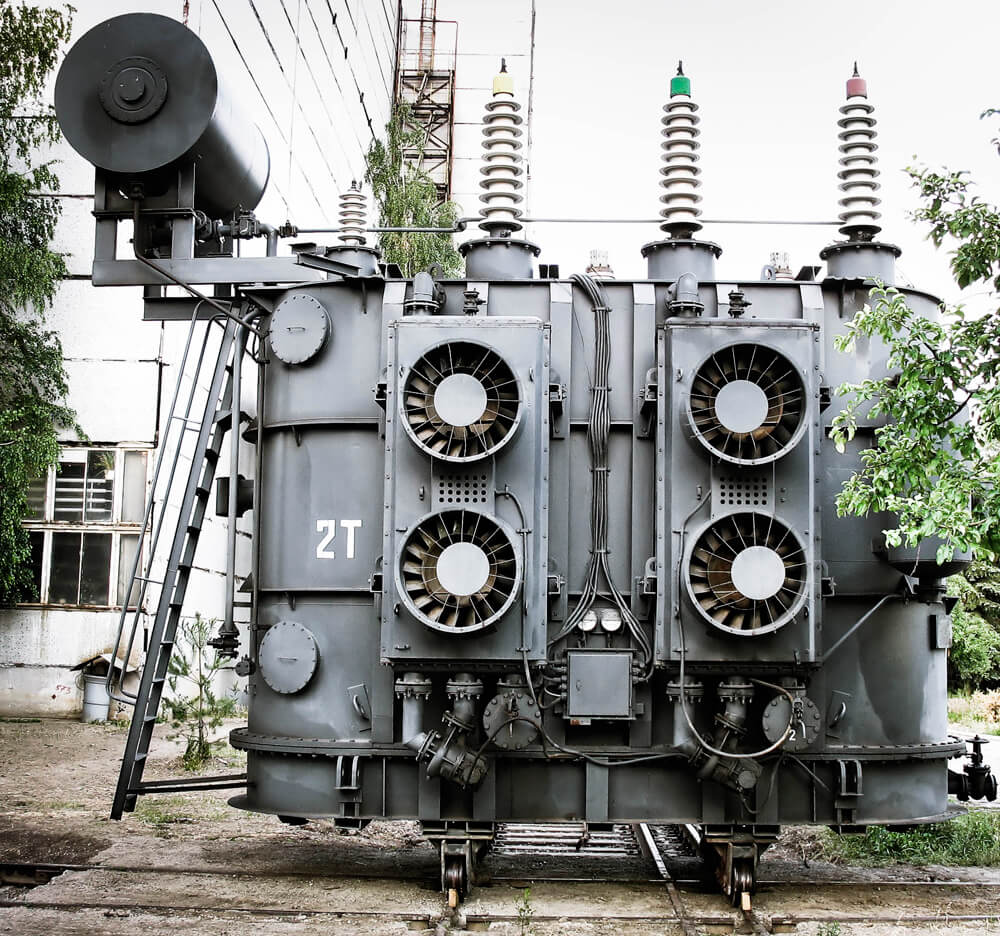

Transformer oil recycling is increasingly acknowledged as a crucial technique in the management of electric facilities. Using transformer oil, necessary for cooling and protecting electrical transformers, results in the accumulation of waste oil that demands accountable handling. Recycling this oil not just conserves beneficial all-natural resources yet likewise plays a critical function in advertising sustainability within the power industry.

Furthermore, transformer oil recycling can significantly decrease operational prices for services and utilities. By recycling oil, organizations can alleviate expenditures connected with acquiring new oil and handling waste disposal. Applying efficient recycling programs mirrors a commitment to ecological stewardship and operational effectiveness, positioning business as leaders in lasting methods within the electric industry. On the whole, the value of transformer oil recycling can not be overstated as it sustains both ecological and financial goals.

Ecological Effect of Improper Disposal

The improper disposal of transformer oil positions substantial environmental dangers that can not be overlooked. Transformer oil typically consists of unsafe substances, including polychlorinated biphenyls (PCBs), which can pollute dirt and water resources if launched right into the environment. When improperly discarded, these harmful chemicals can leach into groundwater, positioning major health risks to local ecosystems and communities.

In addition, transformer oil can interfere with water habitats when it enters bodies of water, leading to destructive results on fish and various other wildlife. The oil develops a movie on the water surface, limiting oxygen exchange and restraining photosynthesis in marine plants. Moreover, the determination of these contaminants in the environment can lead to bioaccumulation in the food web, impacting not only wildlife but likewise human health with the usage of polluted fish and water.

In addition to chemical contamination, inappropriate disposal can cause physical dangers, such as oil spills, which require pricey remediation initiatives. The long-lasting consequences of neglecting correct disposal methods expand past environmental degradation, as areas might deal with economic challenges as a result of reduced all-natural resources and increased healthcare expenses. Re-refining Transformer Oil. Resolving these dangers is crucial for sustainable environmental stewardship

Benefits of Professional Recycling Services

Reliable management of transformer oil via specialist recycling solutions offers many advantages that prolong past mere conformity with environmental laws. One of the main advantages is the decrease of environmental risks associated with inappropriate disposal. By using specialized reusing processes, companies can minimize the threat of soil and water contamination, thereby securing ecological communities and public wellness.

Additionally, professional recycling services contribute substantially to source preservation. Transformer oil can be improved and reused, Discover More reducing the need for brand-new oil production. This not only saves natural deposits yet also lowers energy usage and greenhouse gas discharges linked with oil extraction and refining.

Furthermore, involving with specialist solutions enhances operational effectiveness. Organizations can streamline their waste administration procedures, guaranteeing that transformer oil is taken care of safely and sensibly. This can bring about set you back financial savings in waste disposal and prospective liabilities connected to ecological damage.

The Recycling Process Discussed

Utilizing expert recycling services not just assists in decreasing environmental hazards and preserving sources but additionally entails a methodical method to the recycling procedure itself - Virgin Transformer Oil. The recycling of transformer oil starts with the collection of utilized oil, which is frequently contaminated with numerous impurities, including dust, water, and metal bits

When gathered, the oil undergoes a comprehensive analysis to identify its condition and the necessary treatments required for efficient recycling. Next off, the oil undergoes filtering and filtration procedures, which may consist of vacuum distillation, clay therapy, and degasification. These techniques successfully eliminate contaminants, restoring the oil to a useful state.

After filtration, the recycled transformer oil is evaluated to ensure it satisfies market criteria and specifications. By employing these careful actions, professional recycling services guarantee that transformer oil is recovered successfully, lowering waste and promoting sustainable methods.

Picking the Right Recycling copyright

Selecting the right recycling supplier for transformer oil is an important decision that can considerably affect both ecological sustainability and operational performance. When evaluating potential company, it is vital to consider their accreditations and compliance with environmental regulations. A respectable recycler will certainly abide by national and local criteria, making certain that the reusing procedure lessens ecological injury.

Additionally, examine the service provider's experience and expertise in handling transformer oil. A recognized company with a proven performance history will certainly possess the required innovations and techniques to recycle oil efficiently, protecting its high quality and minimizing waste. Transparency in their processes and readiness to share information regarding their recycling outcomes can additionally suggest a you could try these out trustworthy companion.

Expense top article is an important variable; nevertheless, it should not be the single determinant. Analyze the general value used by the supplier, including their service integrity, client assistance, and the capacity for partnership in future sustainability initiatives. Ultimately, seek endorsements or study from previous customers to determine their fulfillment. By thoroughly weighing these aspects, organizations can select a recycling provider that lines up with their environmental goals while making certain efficient and accountable monitoring of transformer oil waste.

Conclusion

In conclusion, the significance of reputable transformer oil recycling services can not be overemphasized. Inevitably, the fostering of efficient transformer oil recycling practices plays a crucial duty in cultivating a lasting circular economic climate and securing vital ecosystems.

The use of transformer oil, essential for cooling down and protecting electrical transformers, leads to the accumulation of waste oil that demands accountable handling.By reusing transformer oil, business can decrease their dependence on new oil production, which is often resource-intensive and ecologically exhausting. By recycling oil, organizations can reduce expenditures linked with buying brand-new oil and managing waste disposal.Reliable management of transformer oil with specialist recycling services provides many advantages that extend beyond simple conformity with environmental laws. Transformer oil can be refined and reused, reducing the need for brand-new oil manufacturing.

Report this page